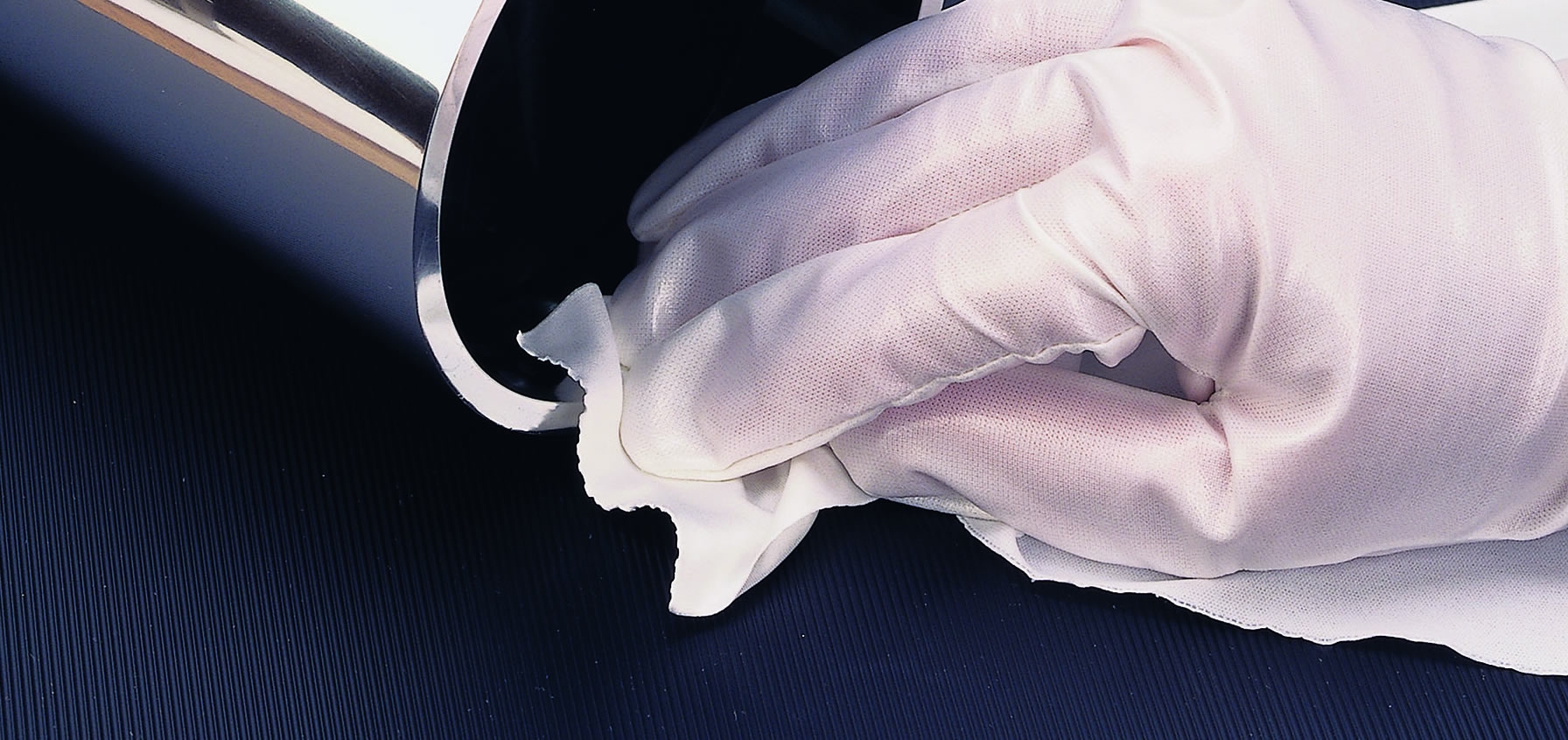

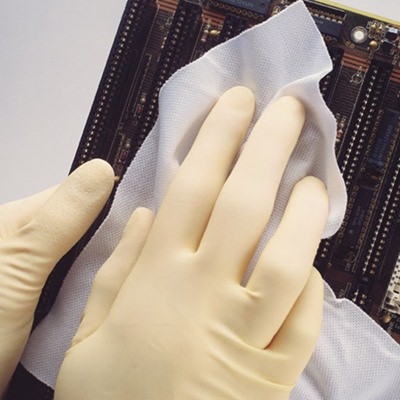

Any wipe will produce particulates depending on the amount of abrasion it receives in use, so abrasion resistance should be considered. Wipes usually release the most particulates from their edges, so using a sealed-edge wipe will greatly reduce the particulate burden. Heat cutting is a common method of creating a sealed edge. A hot knife cuts the edge and simultaneously fuses all the loose ends on the wipe, as in the Coventry Poly-Wipes. The texture of the wipe should also be considered when critical or sensitive surfaces are involved in the application. Some wipes can abrade some critical coated optical surfaces and should therefore be avoided in such applications. Chemtronics Twillwipes (C900) are knit cotton wipers that are also very good on abrassive surfaces.

You did not finish submitting your information to request a sample