Your Sample Request

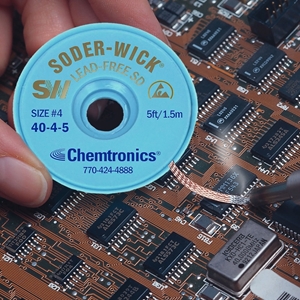

Soder-Wick Lead-Free Desoldering Wick

*=required field

TDS

REGS

SDS

Soder-Wick Lead-Free Desoldering Wick

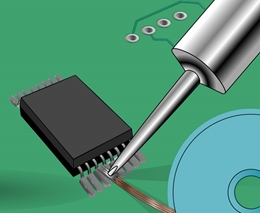

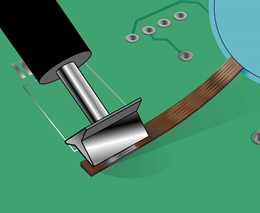

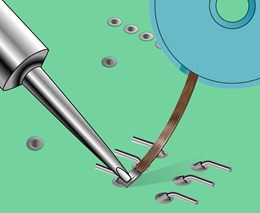

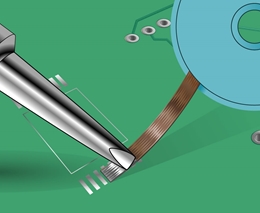

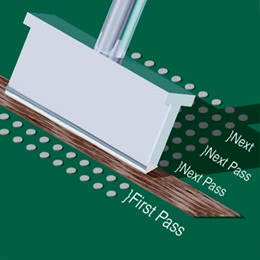

Soder-Wick Lead-Free desoldering wick is the state of the art in desoldering technology. It is specially designed for removal of today’s high-temperature lead-free solders. The single layer weave used for Soder-Wick Lead-Free desoldering wick is lighter in mass than any other desoldering wick available and allows for lead-free solder removal at lower temperatures. Soder-Wick Lead-Free desoldering wick responds faster than any other conventional desoldering braid. This unique design minimizes overheating and requires less “contact” time thus preventing heat damage to the PCB and sensitive components. For Lead-Free rework, Soder-Wick has the answer.

Soder-Wick brand desoldering wick offers the state of the art in desoldering technology. Soder-Wick is designed for today’s heat sensitive electronic components using lighter mass, pure copper braid construction that allows for better thermal conductivity, even at low temperatures. Soder-Wick responds faster than conventional desoldering braids thereby minimizing overheating and preventing PCB damage.

5' and 10' bobbins have 2 packaging options:

|

|

| 25 bobbins in resealable bag | 10 bobbins in resealable pouch |

Features & Benefits

- Engineered specifically for high temperature, lead-free solders

- Transfers heat to the solder joint more quickly and efficiently than conventional desoldering braids

- Can also be used with Tin/Lead solders

- Non-corrosive ultra high purity no-clean flux

- Will not leave ionic contamination on the boards

- RoHS Compliant

- Patent Pending

Specifications:

- MIL-F-14256 F

- NASA-STD-8739.3 Soldered Electrical Connections

- DOD-STD-883E, Method 2022

- ANSI/IPC J STD-004, Type ROL0