Cleanroom swabs are essential tools used in controlled environments, such as cleanrooms, where maintaining high levels of cleanliness and avoiding contamination is crucial. Different types of cleanroom swabs are designed to meet specific requirements and are made from various materials to suit different applications. Some common types of cleanroom swabs include:

- Foam Swabs: Foam swabs are made from polyurethane foam, which has excellent solvent compatibility and high absorbency. These swabs are ideal for cleaning delicate surfaces, applying solvents, and removing excess residues. Foam swabs come in different sizes and shapes to address various cleaning needs.

- Polyester Swabs: Polyester swabs are constructed from a synthetic material that has low particle generation and good chemical resistance. These swabs are often used in precision cleaning applications, particularly in sensitive electronic components and hard-to-reach areas.

- Microfiber Swabs: Microfiber swabs are designed to trap and remove microscopic particles effectively. They are often used in cleaning sensitive optical surfaces, camera lenses, and other high-precision equipment.

- Cotton Swabs: Cotton swabs, also known as cotton-tipped swabs, have a cotton tip attached to a plastic or wooden handle. They are commonly used in less critical cleanroom environments for general cleaning and application of solutions.

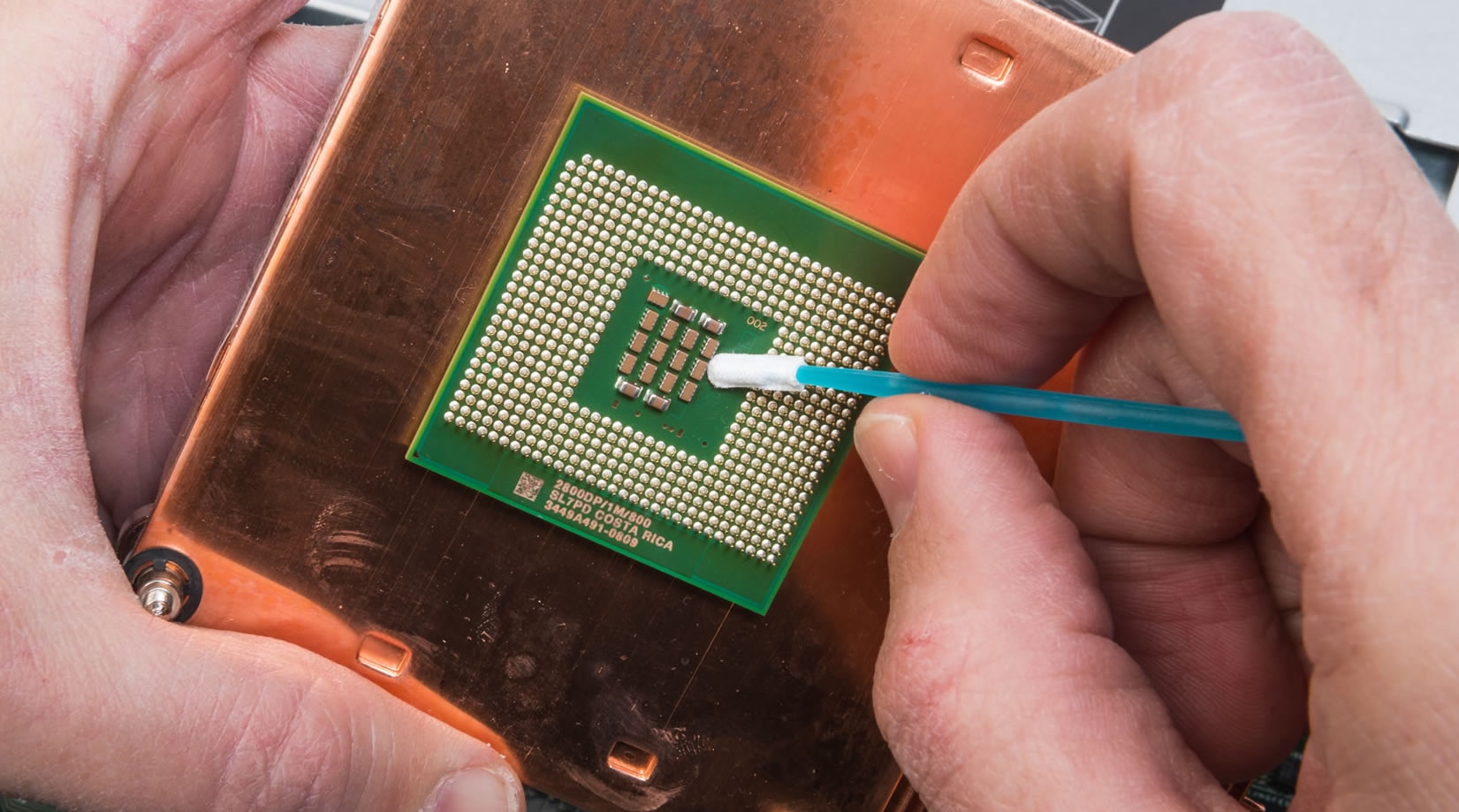

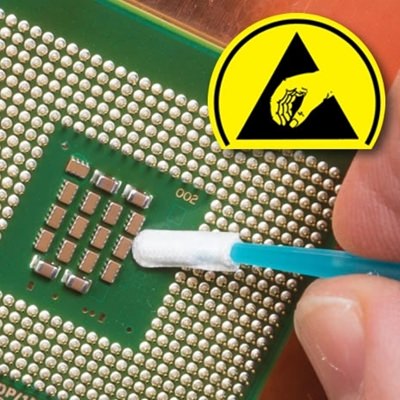

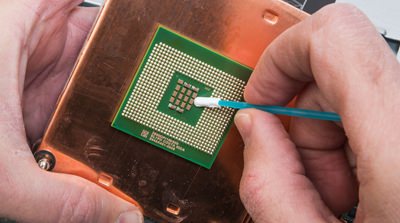

- ESD-Safe Swabs: Electrostatic discharge (ESD)-safe swabs are designed to prevent damage to sensitive electronic components that could be harmed by static electricity. These swabs are usually constructed with conductive materials that dissipate static charges.

It's important to select the right type of cleanroom swab based on the specific needs of the cleanroom environment and the surfaces or equipment being cleaned. Each type of swab has unique characteristics that make it suitable for different applications, so proper selection is essential to ensure effective cleaning and avoid any risk of contamination.