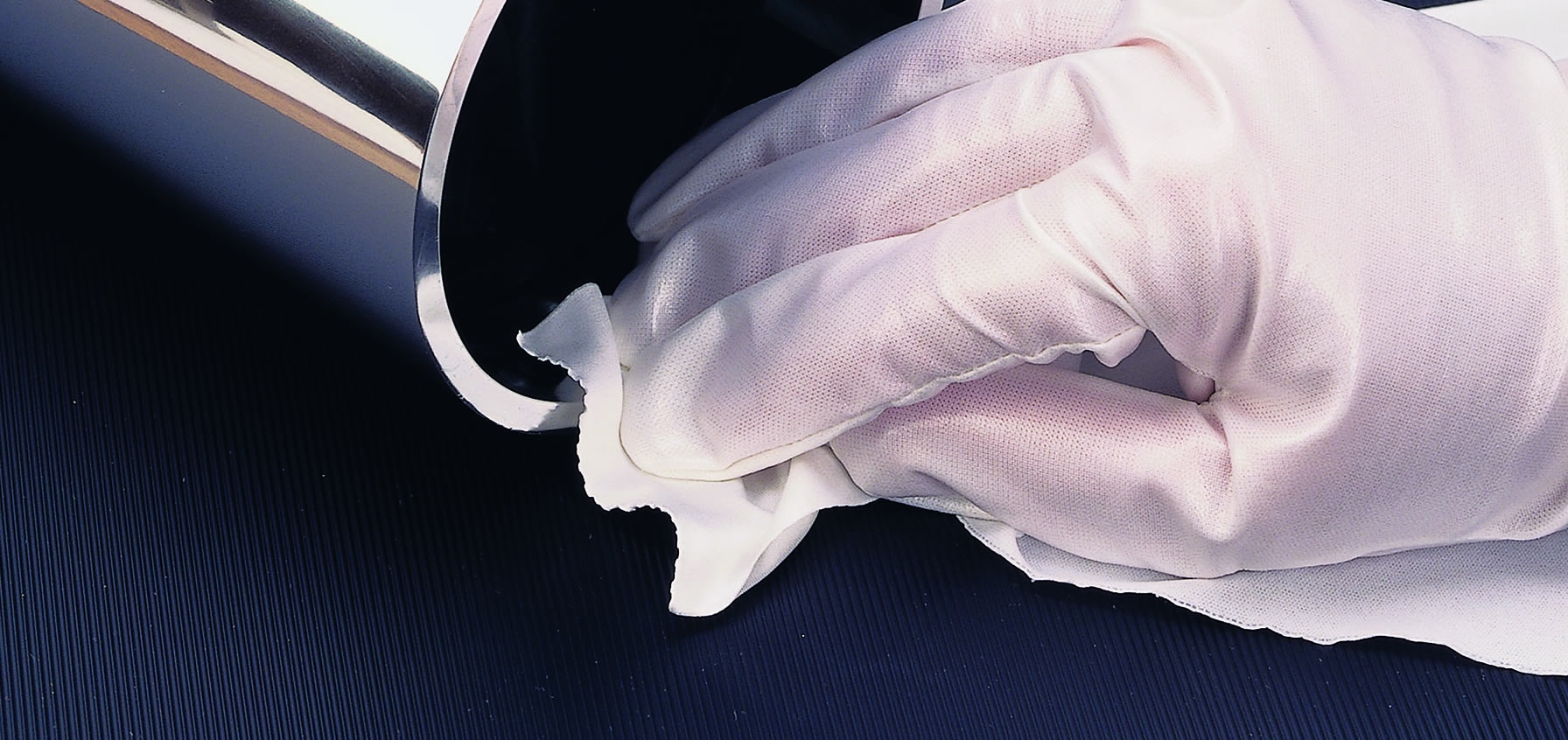

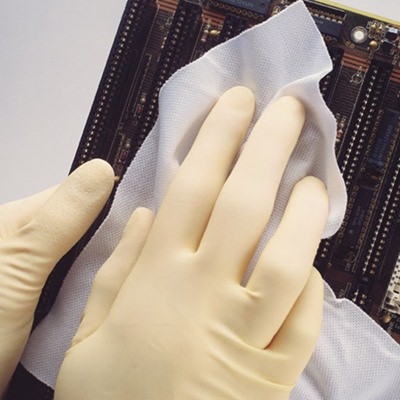

Cleanroom wipes, also known as cleanroom wipers, are specialized cleaning materials used in environments that require high levels of cleanliness and contamination control. These environments are typically found in industries such as semiconductor manufacturing, pharmaceuticals, biotechnology, aerospace, medical device manufacturing, and other fields where even minute particles or contaminants can negatively impact the final product or research outcomes.

Cleanroom wipes are designed to be low-linting, non-abrasive, and made from materials that minimize the release of particles or fibers. They come in various sizes and materials, including polyester, microfiber, polypropylene, cellulose, and blends of these materials. The choice of material depends on the specific cleaning requirements of the cleanroom or controlled environment.

Some key features and characteristics of cleanroom wipes include:

- Low Particulate Generation: Cleanroom wipes are manufactured to have low particle and fiber release to avoid contamination of sensitive equipment and products.

- Absorbency: They are designed to efficiently absorb liquids and clean surfaces without leaving residues or streaks.

- Non-scratching: Cleanroom wipes are soft and non-abrasive to prevent damage to delicate surfaces or equipment.

- Compatibility: Some cleanroom wipes are pre-saturated with cleaning solutions that are compatible with the specific requirements of the cleanroom environment.

- Cleanroom Classification: Cleanroom wipes are available in different classes based on their particle generation and cleanliness level. The class designation corresponds to the ISO cleanroom classification system, such as ISO Class 1, Class 10, Class 100, etc., indicating the number of particles allowed per cubic meter of air.