Hi I’m Mark Quigley, Life Sciences Market Manager for Coventry. Coventry is a brand of Chemtronics, with clean room precision solvents, wipes, and swabs for both sterile and non-sterile applications.

Coventry products are commonly used for biotech...

- Medical applications…

- Lab testing and analysis…

- Medical devices and microelectronics…

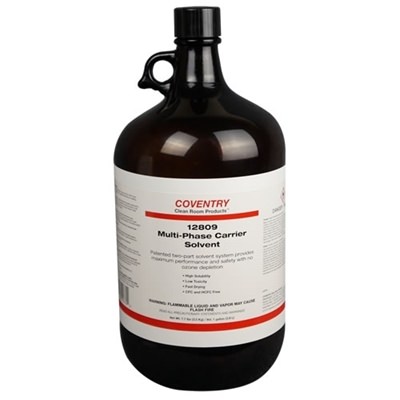

Precision solvents includes high performance cleaners, vapor degreaser solvents, swelling agents, and carrier fluids. Today I’m going to take you through our advanced line of swelling solvents.

Coventry high purity swelling solvents offer medical equipment manufacturers an innovative way to efficiently connect and secure tubing onto connectors without adhesives. Coventry swelling agents provide a cleaner, faster and easier bonding method than other common alternatives like…thermal bonding… solvent bonding… and bonding with medical grade adhesive.

Thermal bonding is a method of attaching tubing to a connector using heat fuse the tube and connector. The disadvantage of this method is it stresses and potentially weakens the connector, increasing the risk of breakage. In addition, plasticizers and other materials within the polymers can leach out.

The solvent bonding method uses an aggressive solvent to partially dissolve and tackify the surface of the materials. Once they harden, the tube and connector mechanically bond together. Similar to a hot welding process, the aggressive solvents can stress the parts. Flexible Tubing can lose its mechanical strength, or begin to breakdown. Rigid plastics can actually craze or crack as the solvents attack the material. In addition, some solvents used in this process are toxic with serious health concerns.

Adhesives are available to bond connectors to tubing. This method can be very effective, but costly. The curing process can also add complexity and potential contamination. UV curable adhesives only cures line-of-site. Cloudy opaque tubing or connectors can block light and cause contamination from the partially cured adhesive.

In contrast to solvent welding, thermal bonding, and medical grade adhesive bonding, Coventry Swelling Solvents have low toxicity, do not stress the assemblies, do not risk contamination from the extractables, and utilize a fast, efficient bonding process.

To use Coventry swelling agents with silicone tubing is a 5-step process:

- Dip about 1” of the end of the tubing into the swelling agent.

- Hold it in the solvent from 5 to 10 seconds, depending on the type and thickness of the silicone.

- Withdraw the tube from the solvent.

The solvent causes the elastomer of the tubing to swell, increasing the size of the opening. - Slide the tube over barb on the connector.

- The solvent will evaporate, causing the tube opening to shrink over the connector, forming a secure, permanent bond.

This can take from five to 15 minutes depending on the size of the tubing. Bonded parts can be handled within minutes.

Pretty much that’s all there is to it! Bonding silicone tubing to a connector with the solvent bonding method is fast, easy, and mess-free. And you don’t have the possibility of toxic fumes and adhesives.

If you have any questions or need help qualifying Coventry swelling solvents into your assembly process, you can contact your local Chemtronics representative or go to coventrycleanroom.com or email us at [email protected].