2021 was a rough year for PCB assemblers who use silicone conformal coating. Many EMS buyers of silicone conformal coating experienced shortages, with lead times going from days to weeks, then even to months. All the while, prices skyrocketed.

Many engineers specify legacy silicone coatings as a “good enough” de facto standard, but shortages in those product lines open the opportunity to consider other materials with superior characteristics. Unfortunately, evaluating new coatings and potentially having to adjust processes to accommodate them may be daunting. The following is a refresher course in silicone conformal coatings.

Silicone Conformal Coating

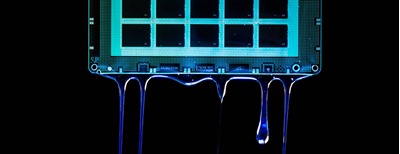

A conformal coating is a specialty polymeric film-forming product that protects circuit boards, components, and other electronic devices from adverse environmental conditions. These coatings ‘conform’ to the irregular landscape of the PCB providing increased dielectric resistance, operational integrity, and protection from corrosive atmospheres, humidity, heat, fungus, and airborne contamination such as dirt and dust.

PCB’s with silicone conformal coating generally have better protection for SIR (surface insulation resistance) degradation than urethane and acrylic coating materials. Silicone conformal coatings are known for their good wetting and adhesion of cured silicone to all surfaces of electronic devices or modules. They are widely used in environments that need to tolerate high temperatures (>120º C), moisture exposure, chemical exposure, corrosive or fungal-prone envirnoments than most other conformal coating chemistries can consistently withstand.

Silicone coatings are most recognized for their stability over wide temperature ranges and during temperature cycling. They are also known to show excellent electrical properties, excellent self-leveling properties, and great mechanical shock resistance due to high flexibility. They are also capable of being applied in thicker films making them useful as a vibration dampening/isolation tool if the coated assembly is to be placed in a high vibration environment.

Conformal Coating Types

How does silicone conformal coating differ from other conformal coating types? Below we'll give a basic breakdown of the distinctions between silicone conformal coating and the other types.

Acrylic conformal coating vs silicone conformal coating: Silicone coating has better mechanical shock resistance (flexibility), is designed for harsher service environments, has better (liquid) water repulsión, better chemical resistance, and is a soft, yet tough and durable.

Urethane conformal coating vs silicone conformal coating: Silicone conformal coating generally has a better mechanical shock resistance, and is generally easier to rework than urethane conformal coating. Urethane conformal coating has good moisture, fungus, and chemical resistances, but some solvent weaknesses. Relative humidity may cause a curing issue for urethane conformal coating.

Epoxy conformal coating vs silicone conformal coating: Epoxy conformal coating is usually two-part products compared to the one-part basis of silicone conformal coating. Silicone coatings offer an easier rework (epoxies usually require some type of micro-abrasion for removal), and does not become brittle over time as many epoxies do.

Parylene conformal coating vs silicone conformal coating: Silicone conformal coating application is much less involved and has a less capital expense than the vapor deposition method used for

Application Methods of Conformal Coating

Manual Spraying

Conformal coating can be applied by an aerosol can or handheld spray gun. Manual spraying is generally used for low volume production when capital equipment is not available. This method can be time-consuming because areas not requiring coating need to be masked. It is also operator dependent, so variations are common from board to board.

Selective Coating

This is an automated conformal coating process that uses programmable robotic spray nozzles to apply the conformal coating to very specific areas on the circuit board. This process is used in high volume processes and can eliminate the need for masking. An applicator may have a built-in UV lamp to cure coating immediately after it is applied.

Dipping

The circuit board is immersed then withdrawn from the conformal coating solution. Immersion speed, withdrawal speed, immersion time and viscosity determine the resulting film formation. It is a common conformal coating technique for high volume processing. A great deal of masking is generally required before the coating process. Dipping is only practical when coating on both sides of the board is acceptable.

Brushing

Brushing is a simple application technique used mainly in repair and rework applications. The conformal coating is applied with a brush to specific areas on the board. It is low cost but labor intensive and highly variable method, best suited for small batches of PCBs.

Dilution

Dowsil 1-2577 and other similar coatings are often purchased in high viscosity formulas (i.e. over 900 cps). This is too thick to be applied through a spray system without causing “

When evaluating replacement coatings, the amount of solvent added may need to be adjusted to achieve the same results. Unfortunately, a simple mathematical calculation based on solids or some other specification isn’t possible because different silicone resins will not weigh the same as the base resin of 1-2577, and may also react differently to the diluent. The conformal coating manufacturer should be able to provide recommendations for the initial process parameters. Viscosity tests should then be performed for the specific application process to ensure that the final coating thickness meets the product requirements.

Cure Methods

Silicone conformal coatings generally cure with exposure to moisture. These materials will react with ambient moisture to form the polymer coating. This type of curing mechanism is often coupled with an evaporative cure. As carrier solvents evaporate, moisture reacts with resin to initiate final curing. When a PCB is coated, the water vapor molecule in the air triggers the polymer chain reaction, so that the wet polymer (small polymers with low molecular weight) is converted into a solid polymer (a larger molecule with higher molecular weight). During this process, the solvent is also evaporated. So curing and drying happen at the same time.

Time to reach a tack-free state or to the coating’s final properties (full cure) can be accelerated with the addition of a heating process. Allow time for the solvent to evaporate before increasing temperatures in an oven. If coating blisters or bubbles, increase time at room temperature for the solvent to evaporate before placing the PCB into the oven.

Certifications

Certifications are an important way to distinguish general purpose varnishes and shellacs from engineered coatings designed specifically for PCB protection. Although there are dozens of users and industry specifications, the two major certifications are IPC-CC-830B and UL746E. When selecting a coating, look for the availability of 3rd-party test documentation, rather than coatings with the claim that it “meets the requirements”. Both standards use the UL94 standard to judge flammability, with a V-0 rating signifying the lowest flammability potential.

IPC-CC-830B / MIL-I-46058C

This standard originated with the military standard MIL-I-46058C, which became obsolete in 1998. The civilian version IPC-CC-830B is nearly identically, so it is generally understood that if a board passes the IPC spec it will also pass the MIL spec., and vice-

- Appearance

- Insulation resistance

- UV fluorescence

- Fungus resistance

- Flexibility

- Flammability

- Moisture and insulation resistance

- Thermal shock

- Hydrolytic stability

- UL94 Flammability Rating

Underwriters Laboratories (UL) is considered a credible and reliable safety certification body worldwide, and UL certification is commonly required for many consumer goods. UL746E tests for electrical safety and flammable safety of the coated electronics. For electrical safety, there is a battery of tests similar to IPC-CC-830B, but with a cycling current load to constantly measure the failure of the insulative properties of the coating. The flammability test uses the UL94 standard like IPC-CC-830B, which involves attempting to light the cured coating with an open flame and observing the sustainability of the flame. Coatings can, and often are, tested to standards that only represent a portion of the whole standard. In the case of UL94, this is helpful when flammability is the main concern. The following are UL94 flammability ratings:

- HB - slow burning

- V-2 - burning stops within 30 seconds, flaming drips are allowed.

- V-1 - burning stops within 30 seconds, non-inflamed drips are allowed.

- V-0 - burning stops within 10 seconds, non-inflamed drips are allowed.

MIL-STD 810G and MS941-04 Salt Spray Tests

Silicone conformal coatings are often selected to protect PCB’s from high moisture, in possibly outdoor environments. More extreme methods of testing for that type of requirement are the MIL-STD 810G salt spray test and MS941-04, which is more common in the automotive industry. These methods are used to evaluate the effectiveness of conformal coatings, and to identify potential problem areas, design flaws, etc., in a relatively short period of time. The salt spray test involves the following steps:

- Condition PCB in the test chamber for 2 hours at 95°F / 35°C.

- Continuously atomize a salt solution into the test chamber for 24 hours.

- Dry the test item at ambient temperatures and relative humidity (RH) of less than 50% for 24 hours.

- After the drying period, repeat steps 1 to 3 at least once.

- After completing the physical and any electrical checkouts, document the results with photographs and visually inspect the test item.

Regulatory Considerations

Of course, safety and environmental considerations should always play a part of the chemical selection and process design, but the various regulatory bodies make this even more challenging as requirements have to be interpreted and matched with product specifications.

OSHA (Occupational Safety and Health Administration)

In the US, OSHA has overriding authority over worker safety concerns. Many coatings are very flammable, and many emit fumes that have a high level of toxicity. Close attention needs to be paid to ventilation (and explosion-proof when dealing with flammable fumes) and the appropriate PPE (personal protection equipment) to keep operator exposure below safety thresholds. Flammability may be difficult to avoid without exploring more niche water-based coating materials. Newer coatings have been introduced that don’t include HAPs (hazardous air pollutants – a government classification of particularly toxic chemicals) like toluene, methylene chloride or methyl ethyl ketone (MEK). Global Harmonized System (GHS – with the tell-tale red diamond symbols) needs to be followed for labeling, which is generally taken care of by the manufacturer. Safety data sheets (SDS) should be readily available to operators, as they are with any hazardous chemical in a facility.

EPA (United States Environmental Protection Agency)

In the US, EPA requirements must be followed at the national and regional level. The EPA, following the Montreal Protocol treaty, enforced restrictions on ozone-depleting chemicals. Since most of the restricted chemicals are now unavailable and haven’t been used in conformal coating formulation for years, ozone depletion isn’t the current concern. If there are regional agencies (see next paragraph) that have stricter requirements than the EPA, those generally will need to be followed.

CARB (California Air Review Board) and other regional regulators

Local agencies have an increasing role in environmental restrictions. CARB was one of the early regulatory bodies, laying down VOC (volatile organic compounds – smog-producing chemicals) restrictions by product category. Other regional agencies followed their lead. Global warming potential (GWP) is the latest environmental topic of discussion.

Konform SR-X Silicone Conformal Coating – The 1-2577 and 1-2620 Alternative

Konform SR-X is a one-part, ultra-clear silicone conformal coating with a moisture- and abrasion-resistant surface. Konform® SR-X was developed to replace or substitute legacy silicone conformal coatings like Dowsil 1-2577 and 1-2620 as availability came into question, and pricing became increasingly volatile. This coating offers a resilient, mechanical stress-reducing protection, with reduced VOC content. Utilizing a moisture/humidity-based curing mechanism, this coating cures quickly at ambient conditions.

- Application methods – Available in ready-to-use viscosities for minimal process adjustments.

- Dilution – Can be diluted using standard, low moisture-containing solvents like toluene and acetone.

- Curing methods – Can be cured in ambient conditions or accelerated at elevated temperature.

- Certifications – Meets the requirements of IPC-CC-830B and MIL-I-46058C, has V-0 UL94 flammability rating and passes the MIL-STD 810G salt spray test.

- Regulatory compliance – Low VOC and does not contain toxic solvents like toluene, xylene, and MEK.

For tech data sheets (TDS) or safety data sheets (SDS), go to www.chemtronics.com. To talk to a technical specialist or request a sample, please call 770-424-4888 x111 or email [email protected].

Chemtronics has a great solution with our new Konform® SR-X Silicone Conformal Coating. It is engineered to replace the most common silicone conformal coatings, like Dowsil 1-2577, with performance characteristics as good if not better. The material of SR-X meets the requirements of IPC-CC-830B and MIL-I-46058C, has V-0 UL94 flammability rating, and passes independent MIL-STD 810G and MS941-04 salt spray tests. And best of all, the base silicone is not impacted by the current shortages, so supply is readily available with short lead times, and stable pricing!