Pumps are devices that deliver or transfer fluids or gases in the process of suction or pressure. Examples in the medical field are infusion pumps, syringe pumps, and feeding pumps. These devices use the concept of pressure to automatically deliver medications, fluids, and processed food.

Infusion pumps are the devices that deliver intravenous fluids or medication automatically to a patient. These devices can be seen mostly in the ward, emergency room or intensive care unit of hospitals. Accuracy is important; even for benign substances like IV fluids, overloading a patient can lead to headaches, high blood pressure, cramping, trouble breathing, or anxiety.

There are ways to prevent these problems. These include proper calibration, proper operation, and proper maintenance of the machine.

Here are some tips on how to eliminate overloading or underloading IV fluids on a patient.

Proper Calibration

An infusion pump is initially calibrated by the manufacturer but there are cases where the calibration is incorrect. Using the machine for a long time can also lead to the inaccurate delivery of IV fluid to a patient. To calibrate the machine:

- Prepare IV tubes and volume measuring devices.

- Set a target volume and run the machine.

- Measure the actual volume infused by the machine and compare it to the target volume.

- Adjust the calibration factor and perform a test run to verify the accuracy.

Proper Operation

End-user training is important to prevent human errors. Product specialists or engineers need to endorse every function to the nurses. Aside from the functions, basic error troubleshooting must be endorsed too. With training, future problems can be prevented.

- Install the IV tube to the Infusion pump. Make sure that the IV installation area is clean and free from dirt to avoid contamination.

Note: Ensure that the IV tubing to be used is compatible or calibrated to the Infusion pump to avoid overloading or underloading of IV fluids or medications. - Close the door and release the roller flow controller of the IV tube. Ensure that roller flow control is released to avoid occlusion detection.

- Power-on the machine by long pressing the on/off button, the same process as turning off the machine. Pumps are battery-operated and have a built-in smart charging module, but should be plugged-in while in use inside the hospital, reserving the batteries for emergency situations, patient transport, and interrupted power. After powering it on, the machine will undergo self-tests. Make sure that there are no errors before using the machine.

- Purge the IV Fluid. Make sure that IV fluid will flow at the end of the IV tubing.

- Install the IV tube to the patient.

- Set the flow rate or the time for infusion.

- Set the amount or volume to be infused to the patient.

- Press the start button to start the infusion.

- After infusing the set volume, each machine is equipped with a KVO function to prevent clotting.

- Power-off the machine after use. Make sure to clean the machine right after use.

Proper Maintenance

Infusion pumps are comprised of these basic components: Motor, Peristaltic pump, power supply, sensors, LCD display, and Microcontroller. Each component requires maintenance.

|

|

Motor Servo motors are used for the infusion pump system. Disassemble the motor and gear part of the Infusion pump. To clean the motors and the gears, prepare a paper towel and use Chemtronics Electro-wash degreasers to remove contaminated grease. |

|

|

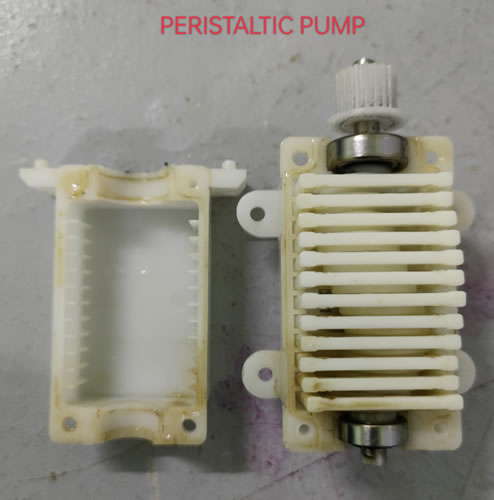

Peristaltic pump The Peristaltic pump works together with the motor. Together they are responsible for the mechanical movement for the flow control of the Infusion pump. To clean this, disassemble the peristaltic pump and prepare a paper towel and Chemtronics Electro-wash degreaser to remove excess contaminated grease. |

|

|

Power supply The Power supply is the heart of the infusion pump. The most common power supply errors are battery lost, AC lost, or not charging. Connectors may be loose or dirty which then interferes with the contact between the battery and the power supply module, or the fuse is broken. In this latter case we just need to replace the fuse with another one. For cleaning the connectors and the power supply module, prepare Chemtronics Coventry cleanroom swabs and clean the connectors. For the module, use the Chemtronics Electro-wash degreasers to remove excess dirt. |

|

|

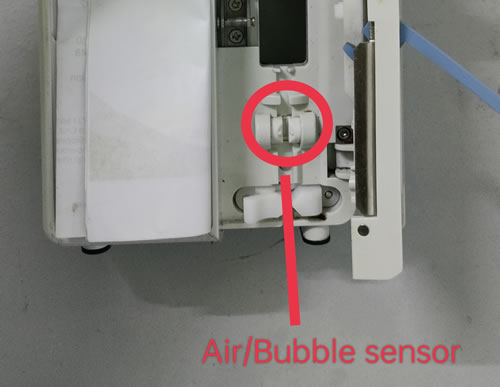

Sensors There are different sensors used for the infusion pump. Door sensors, pressure sensors, motor sensors, drop sensors, and air bubble sensors are common. Door sensors and motor sensors are electromagnetic sensors. Presaturated Chemtronics swabs and wipes clean the magnets. Drop sensors and air bubble sensors use ultrasonic sensors. To clean these sensors, prepare Chemtronics Coventry cleanroom swabs and remove excess dirt on the sensors. |

|

|

LCD display LCD display and keypad are the most prone area to become dirty. To maintain a clear display, frequent cleaning is a must. Use alcohol wipes to remove dirt and other bacteria. |

|

|

Microcontroller To clean the microcontroller, or brain of the Infusion pump, we need to clean the excess dirt on the electronics circuit boards using cleanroom swabs. |

(Note: Swabs and wipes are not reusable.)

In the medical field, every detail is crucial. We need to ensure the complete safety and accuracy of the machines and proper maintenance will help us to achieve that standard. Save a life by doing proper maintenance!

Ask A Technical Question

Stay up-to-date on Chemtronics news, products, videos & more.