Coventry™ Swab Selection Guide

- Foamtip Swabs

- Flextips & Super Flextips

- Chamois Tips

- Microtip Swab

- Cottontip Swabs

- Sealed Polyester Swabs

- Sealed Foam Swabs

- ESD Static Control Swabs

- Wrapped Foam Swabs

- Diamond Swabs

- Pillow-Tip Swabs

- Fiber Optic Connector Cleaning Swabs

- FAQ

Choose the ideal swab for your process with confidence. This guide compares wrapped, sealed foam, sealed fabric, and static-control options - covering tip geometry, handle type, ESD properties, particle performance, and solvent compatibility - so you can protect delicate surfaces, control contamination, and improve yield in cleanroom and electronics rework.

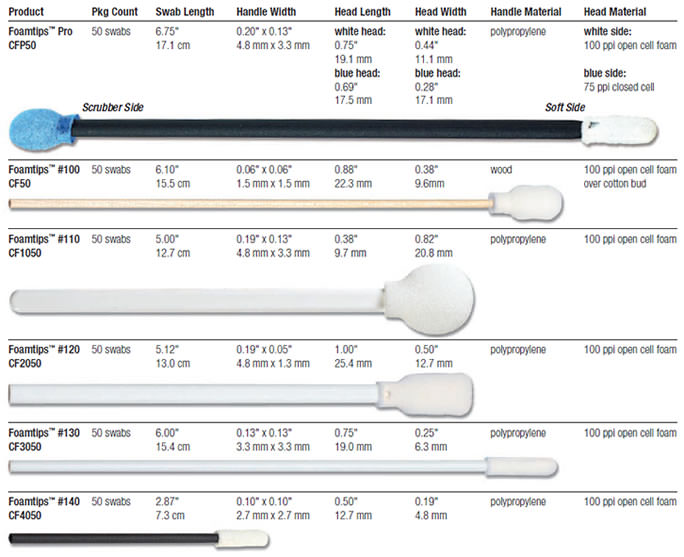

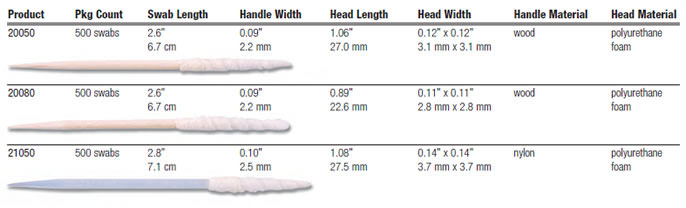

Foamtip Swabs

Foamtips™ Swabs feature medical-grade, open-cell polyurethane foam for excellent particle capture and solvent absorption. The foam head is thermally bonded to the handle - no adhesives or binders - making it ideal for general precision cleaning.

Features & Benefits

- Medical-grade foam for clean, consistent performance

- High solvent capacity and particle entrapment

- Fiberless, non-abrasive construction

- Economical for high-volume use

Applications

- Remove flux and excess adhesive

- Clean micro-mechanical parts

Apply controlled amounts of lubricants or adhesives

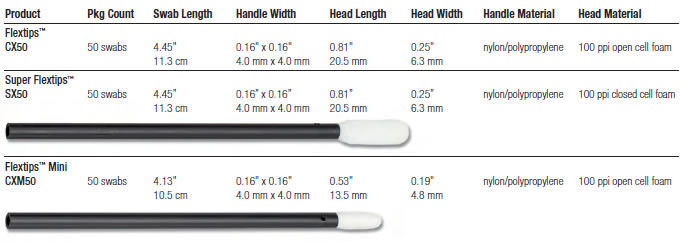

Flextips & Super Flextips

Flextips™ and Flextips™ Mini Swabs feature a durable nylon paddle and 100 ppi medical-grade foam head for precise, nonabrasive cleaning. The foam is thermally bonded - no adhesives or binders - for strength and cleanliness in critical applications.

Features & Benefits

- Strong yet flexible nylon paddle won’t break

- Fine-cell foam traps particles and holds solvent

- Gentle, fiberless construction for sensitive surfaces

- Economical for high-volume use

Applications

- Clean flux, adhesives, or residues

- Wipe delicate micro-mechanical parts

- Apply precise amounts of lubricants or adhesives

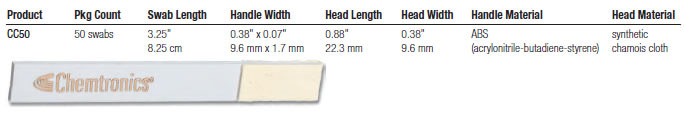

Chamois Tips

Coventry™ Chamois Tip Swabs are designed for precision cleaning of sensitive magnetic and optical components. The synthetic chamois head provides gentle, residue-free contact - ideal for removing particles or films that could interfere with signal performance in data storage or imaging equipment.

Features & Benefits

- Lint-free synthetic chamois ensures streak-free, nonabrasive cleaning

- Oil-free material leaves no residue or contaminants behind

- Flexible ABS handle allows access to compact or recessed areas

- Adhesive-free bonding supports use in cleanroom and precision environments

Applications

- Cleaning magnetic and optical heads during equipment maintenance

- Safely removing particles and residues from read/write assemblies

- Ideal for use with isopropyl alcohol (IPA) or Chemtronics solvent cleaners

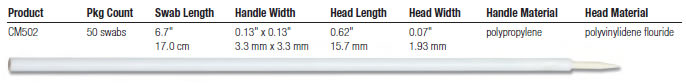

Microtip Swab

Microtips™ Swabs feature a tapered porous polyvinylidene fluoride (PVDF) tip for pinpoint precision in tight spaces. The tip is solvent-compatible and assembled without adhesives, making it ideal for controlled application of adhesives and lubricants.

Features & Benefits

- Porous PVDF tip ensures low particulates and extractables

- Compatible with most solvents, adhesives, and coatings

- Tapered 1.925 mm design enables stylus-like precision

- Adhesive-free assembly for cleanliness and reliability

Applications

- Dispensing and spreading solvents, adhesives, and primers

- Precision work requiring tight-tolerance cleaning or application

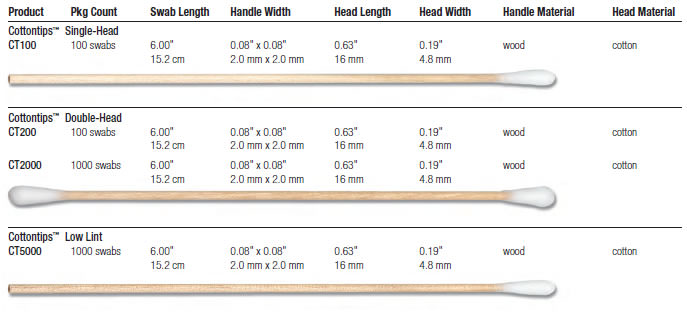

Cottontip Swabs

Coventry™ Cottontip Swabs provide a simple, economical option for cleaning and application tasks that require maximum absorbency with minimal linting. The tightly wrapped cotton head delivers reliable fluid pickup and release, making these swabs suitable for general maintenance, touch-up work, and solvent application in non-critical areas.

Features & Benefits

- Tightly wound pharmaceutical-grade cotton for dependable absorbency

- Available in single or double head configurations for flexibility in use

- Compatible with most common solvents and cleaning agents

- Strong wooden handle offers stability for controlled cleaning and application

Applications

- Absorbing and removing flux, dust, or light residues during assembly or repair

- Applying lubricants, adhesives, or coatings to small or detailed surfaces

- General-purpose cleaning in production, rework, or laboratory settings

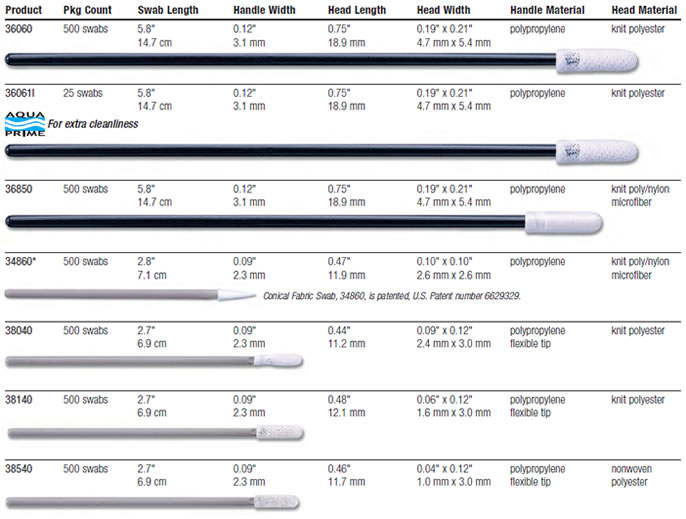

Sealed Polyester Swabs

Coventry™ Sealed Polyester Swabs are built for critical environments where cleanliness, strength, and solvent compatibility are non-negotiable. The sealed knit or nonwoven polyester head provides excellent particle retention and chemical resistance, making these swabs ideal for controlled cleaning, validation, and surface preparation in ISO-class facilities.

Features & Benefits

- Sealed, adhesive-free head construction ensures low particle and residue levels

- High absorbency and solvent resistance for precise cleaning performance

- Smooth, fiber-free edges reduce risk of snagging or contamination

- Available in knit or microfiber options to match cleaning aggressiveness and retention needs

- Produced in Class 10 (ISO Class 4) cleanroom conditions for purity assurance

- Optional Aqua-Prime™ process for enhanced cleanliness in critical applications

Applications

- Surface cleaning and validation in pharmaceutical, biotech, and cleanroom manufacturing

- Precision cleaning of optics, disk drives, and instrumentation surfaces

- Removal of residues and particulates from aerospace and electronic assemblies

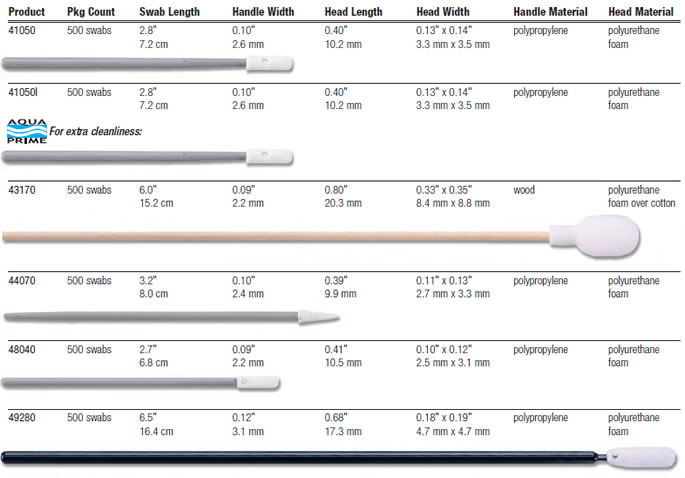

Sealed Foam Swabs

Coventry™ Sealed Foam Swabs are designed for versatile, cost-effective cleaning where durability and solvent compatibility are essential. The 100 ppi open-cell foam provides balanced absorbency and particle capture, making these swabs an excellent option for routine maintenance and controlled cleaning in production or rework environments.

Features & Benefits

- Durable, medical-grade foam delivers consistent solvent release and pickup

- Open-cell structure enhances absorbency and particle entrapment

- Adhesive-free thermal bonding ensures compatibility with sensitive materials

- Fiberless construction minimizes contamination risk

- Available with Aqua-Prime™ processing for higher cleanliness requirements

Applications

- General-purpose cleaning in assembly, repair, and inspection areas

- Removing flux, dust, and residue from PCBs and electronic components

- Cleaning connectors, housings, and precision mechanical assemblies

- Applying or wiping solvents during production and rework

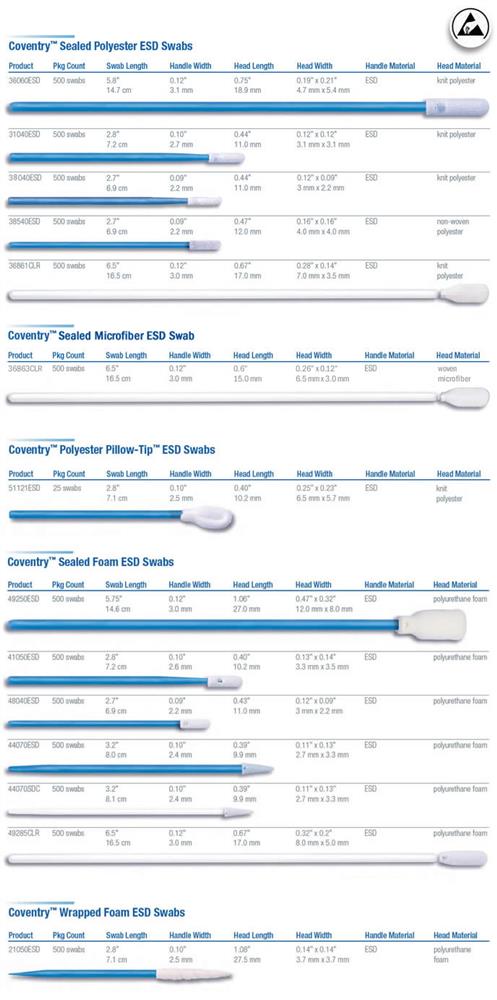

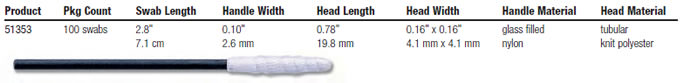

ESD Static Control Swabs

Coventry™ ESD Static Control Swabs are engineered for cleaning and maintenance in static-sensitive environments where electrostatic discharge can damage components. Their inherently dissipative handles and cleanroom-grade heads provide consistent, solvent-resistant performance without additives or humidity dependency - ideal for electronics assembly, testing, and repair applications.

Features & Benefits

- Inherently static-dissipative handles maintain performance without coatings or surfactants

- Rapidly neutralizes electrostatic charge for safer work on ESD-sensitive devices

- Compatible with both knit polyester and 100 ppi foam heads for varied applications

- Solvent- and acetone-resistant for use with aggressive cleaners

- Low ionic, particulate, and nonvolatile residue generation for cleanroom compatibility

- Stable resistivity across humidity ranges for consistent static protection

Applications

- Cleaning static-sensitive components in electronics manufacturing and repair

- Maintenance of circuit boards, sensors, and optical assemblies

- Precision cleaning in environments requiring controlled electrostatic performance

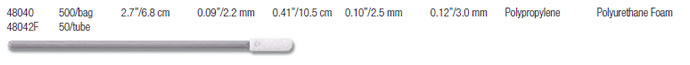

Wrapped Foam Swabs

Coventry™ Wrapped Foam Swabs are engineered for precision cleaning where both strength and absorbency are critical. The wrapped design provides enhanced durability and wicking performance, making these swabs well-suited for controlled solvent application and contaminant removal in confined or high-friction areas.

Features & Benefits

- Wrapped construction improves solvent control and reduces particle release

- Dense foam head withstands repeated use and surface friction

- Non-linting materials support cleanroom and electronics rework applications

- Adhesive-free assembly maintains compatibility with sensitive processes

- Consistent, durable performance for demanding cleaning environments

Applications

- Controlled application or removal of solvents and flux residues

- Cleaning and maintenance of fiber optic connectors and splicing tools

- Precision work on electrical contacts, assemblies, and tight-tolerance components

- Light abrasion or polishing of oxidized or particulate-contaminated surfaces

Diamond Swabs

Coventry™ Diamond™ Swabs are designed for critical cleaning tasks that demand durability and ultra-low particle generation. The seamless tubular-knit polyester head provides gentle yet effective contact, allowing technicians to maintain surface integrity while removing contaminants from precision components.

Features & Benefits

- Seamless, edge-free construction reduces abrasion on delicate surfaces

- Tubular-knit polyester provides excellent strength and solvent compatibility

- Low particulate and nonvolatile residue performance for ISO-class environments

- Adhesive-free assembly ensures cleanroom suitability

- Enhanced wicking and absorbency for controlled solvent application

Applications

- Cleaning precision assemblies, disk drive components, and optical devices

- Removing residues from aerospace and electronic manufacturing surfaces

- Verifying cleanliness during pharmaceutical and biotech production validation

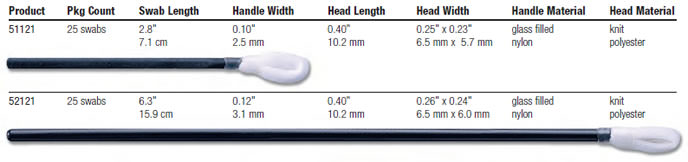

Pillow-Tip Swabs

Coventry™ Pillow-Tip™ Swabs are engineered for critical cleaning where absorbency and cleanliness are equally important. The soft, rounded polyester head offers controlled solvent release without fiber shedding, making it ideal for technicians who need precision cleaning in high-reliability manufacturing and validation environments.

Features & Benefits

- Rounded, seamless polyester tip delivers uniform contact for consistent cleaning

- High solvent retention for controlled wet cleaning applications

- Rigid glass-filled nylon handle provides strength for precision use

- Adhesive-free construction minimizes ionic and particulate contamination

- Compatible with aggressive solvents and Aqua-Prime™ processing for ISO-class environments

Applications

- Controlled cleaning of sensitive aerospace, optics, and disk drive components

- Applying solvents or coatings in tight or delicate areas

- Surface validation and contamination control in pharmaceutical and biotech facilities

Fiber Optic Connector Cleaning Swabs

Coventry™ Fiber Optic Connector Cleaning Swabs are optimized for maintaining signal integrity in fiber optic systems. Built for precise, residue-free cleaning, they help technicians select the right tip size and solvent pairing to safely remove oils, dust, and polishing debris from critical connection points.

Features & Benefits

- Available in multiple diameters to match common connector types (LC, SC, ST, and MTP)

- Seamless, low-lint materials prevent cross-contamination and optical loss

- Compatible with Electro-Wash® PX, CZ, and other Chemtronics fiber optic cleaners

- Designed for both wet and dry cleaning of end faces and adapter sleeves

- Ensures consistent optical performance during assembly, testing, and maintenance

Applications

- Cleaning connector end faces, alignment sleeves, and backplane adapters

- Removing slurry or residue from ferrule polishing fixtures

- Maintaining optical clarity in test ports and high-density connections

Shop Fiber Optic Connector Cleaning Swabs

FAQ

What makes Coventry™ cleanroom swabs different?

Coventry™ swabs are manufactured using engineered clean materials and processed in a Class 10 (ISO Class 4) cleanroom. Each swab type - wrapped, sealed fabric, sealed foam, or static control - is designed to minimize contamination, improve yield, and deliver consistent performance.

What is the Aqua-Prime™ process?

The Aqua-Prime™ process is available on select Coventry™ swabs to achieve the highest levels of cleanliness. Swabs processed this way have lower ionic, nonvolatile residue, and particle contamination, making them ideal for critical cleanroom applications.

What are sealed polyester swabs used for?

Coventry™ Sealed Polyester Swabs are designed for use in cleanrooms and other controlled environments. They are ideal for validating pharmaceutical surfaces, cleaning disk drive components, optics, and aerospace hardware - anywhere high strength, solvent resistance, and low residue are required.

When should I choose a foam swab instead of polyester?

Foam swabs, such as Coventry™ Sealed Foam or Wrapped Foam Swabs, are best for general-purpose cleaning, applying adhesives or lubricants, and removing flux or contamination. They offer high solvent capacity and particle entrapment. Polyester swabs are recommended for applications requiring higher strength, lower residue, or cleanroom-grade performance.

Which swabs are best for cleaning fiber optic connectors?

Coventry™ Fiber Optic Connector Cleaning Swabs are designed specifically for fiber optic maintenance. Made from low-lint, adhesive-free materials, they safely remove dirt and oil contamination from fiber optic end faces, alignment sleeves, polishing fixtures, and test ports.

Can Coventry™ swabs be used with solvents?

Yes. Coventry™ foam and polyester swabs are compatible with most solvents and resist degradation during cleaning. ESD swabs are also solvent-resistant, even to aggressive agents like acetone.

Which industries use Coventry™ and Chemtronics swabs?

These swabs are widely used in electronics assembly, aerospace, fiber optics, disk drive manufacturing, biotechnology, and pharmaceutical validation - any environment requiring precision cleaning and contamination control.