For those of you considering dip applications in your conformal coating process, the following are general guidelines to bear in mind

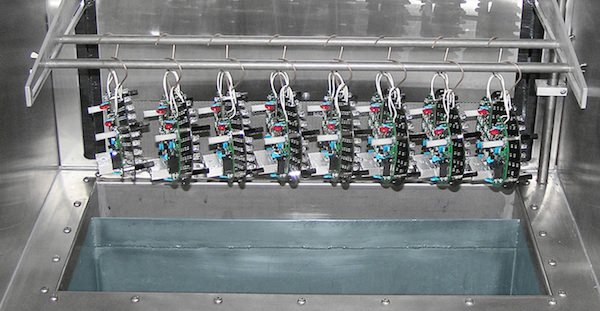

There are a number of variations of dip coating methods for PCBs. The most basic is the manual (by hand) method. Others include variations of automated methods such as the “original” method (automated version of the manual method), batch systems as well as inline systems, and even selective dip coating equipment which eliminates the need for intense masking of sensitive components and other keep-out areas.

Regardless of which method you use, these are some guidelines that you should follow. As always, these are general rules, so please ensure you are extremely safety-conscious when setting up a manual system or contact your equipment manufacturer for instructions for the specific automated model you’re using.

- Make Sure the PCB Is Thoroughly Clean

The circuit board should be clean of all flux residues, process oils and other contaminants to ensure the coating can properly adhere and flow during the operation. Inadequate cleaning can result in dewetting in contaminated areas or delaminating once the unit is in the field. - Use Custom Mask Caps

Obviously, all masking must be done prior to coating set-up. Precision and consistency are key for this. For that reason, custom mask caps for these areas are recommended to maintain consistency to the unit as well as the convenience of use for the operator. - Avoid Coating Buildup

Orient the assemblies to drain to a corner if feasible rather than having a buildup of coating along the bottom unit edge. This may not be possible due to the assembly shape, geometry and /or component population density. - Determine Immersion Speed

The speed must be smooth and slow to allow the coating to penetrate the stand-off areas and avoid trapping air under components. - Determine Immersion Dwell Time

Allow adequate time (generally less than a minute) for the coating to fill all the necessary spaces to be coated. - Determine Withdrawal Speed

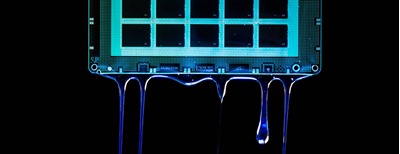

Contrary to what you may think, slower withdrawal results in a thinner wet film due to the balance of forces from the fluid density, viscosity, and surface tension as well as the finish of the laminate material. Thinner wet films yield thinner cured coatings. - Determine Cured Film Thickness

Determine the acceptable range of cured film thickness and work backward to find the optimum withdrawal rate. Maintain coating viscosity as consistently as possible. Changes in viscosity will affect your cured film build over time. Manual systems may need a thinner of some sort added occasionally. Automated models may offer the option of temperature-controlled tanks as well as inert gas blankets to mitigate viscosity drift. - Be aware of the coating formulation and the required conditions or procedures to maintain operator safety.

Again, for those of you using automated systems, always consult with the manufacturer on the proper operation of your specific model. If you have any questions on conformal coating, including other application methods such as conformal coating spray, contact us, and we'll have a specialist help you.

Photo courtesy of SCH Technologies